Address

304 North Cardinal St.

Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

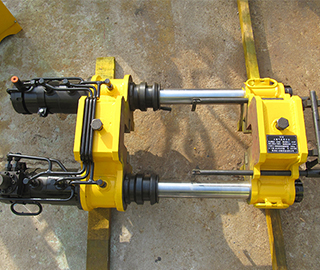

YH/6 GAS WELDING MACHINE

The orbital welding machine is designed for rail welding, utilizing a pressurized deburring method. The press is positioned at the rail bottom to maintain rail head straightness, ensuring precise alignment. It is equipped with an upsetting control valve to prevent operational delays. Compared to similar products, this machine stands out with its innovative design, well-engineered structure, and user-friendly operation.

SPECIFICATIONS OF THE YH/6 GAS WELDING MACHINE

| Model | YH-6 Mobile Rail Gas Pressure Welding Equipment Manual |

| Dimension | 1320*635*330mm |

| Material | stainless steel |

| Color | yellow |

| Application | rail tack welding |

| 1.press | ||

| max. working stroke | 100mm | |

| max.rated working pressure | 35Mpa | |

| max. working pressure | 40Mpa | |

| deburing unit max.working stroke | 120mm | |

| deburring unit max.working pressure | 45MPa | |

| deburring unit max.deburring force | 452kN | |

| press weight | 230kg | |

| press dimention | 1320*635*330mm | |

| 2. hydraulic pump station | ||

| motor voltage | 380V | |

| motor rpm | 1440r/min | |

| pump flow | ≥4L/min | |

| oil tank capacity | 20L | |

| 3. water pump | ||

| type | YSB(AOB)-25 | |

| voltage | 380V | |

| flow | 25L/min | |

YTT-200 HYDRAULIC RAIL JOINT DEBURRING MACHINE

The YTT-200 hydraulic rail joint deburring machine utilizes manual hydraulic transmission, offering a simple structure, compact size, and lightweight design for easy portability and operation. It is suitable for 75kg/m rails and supports both dry and wet thermite welding processes for slag removal. The machine effectively removes weld reinforcement, gates, and risers from the rail top and upper edge. Designed for engineering construction and new railway line projects, it serves as an ideal tool for rail maintenance and repair.

SPECIFICATIONS OF THE YTT-200 HYDRAULIC RAIL JOINT DEBURRING MACHINE

| Model | YTT-200 |

| Max. thrust (double cylinder) | 150KN |

| Max. handle working torque | 120J |

| Working cylinder diameter | 50mm |

| Effective Length | 140mm |

| Handle swing angle | 38° |

| Working cylinder diameter | 50mm |

| Hydraulic system Pressure | 40 Mp |

| Dimension | 900*400*380mm |

| Weight | 65Kg |

| Application | Various rails (50-75kg/m) at the depot or on the track. |

OXY-ACETYLENE GAS PRESSURE WELDING EQUIPMENT

The Oxy-Acetylene Rail Gas Pressure Welding Equipment is designed for rail welding. The press is positioned at the rail bottom to maintain rail head straightness and is equipped with an upsetting control valve to prevent operational delays. It features an innovative design, a well-structured layout, and user-friendly operation.

SPECIFICATIONS OF THE OXY-ACETYLENE GAS PRESSURE WELDING EQUIPMENT

| Model | YH-6 Mobile Rail Gas Pressure Welding Equipment Manual |

| Dimension | 1320*635*330mm |

| Material | stainless steel |

| Color | yellow |

| Application | rail tack welding |

| 1.press | ||

| max. working stroke | 100mm | |

| max.rated working pressure | 35Mpa | |

| max. working pressure | 40Mpa | |

| deburing unit max.working stroke | 120mm | |

| deburring unit max.working pressure | 45MPa | |

| deburring unit max.deburring force | 452kN | |

| press weight | 230kg | |

| press dimention | 1320*635*330mm | |

| 2. hydraulic pump station | ||

| motor voltage | 380V | |

| motor rpm | 1440r/min | |

| pump flow | ≥4L/min | |

| oil tank capacity | 20L | |

| 3. water pump | ||

| type | YSB(AOB)-25 | |

| voltage | 380V | |

| flow | 25L/min | |

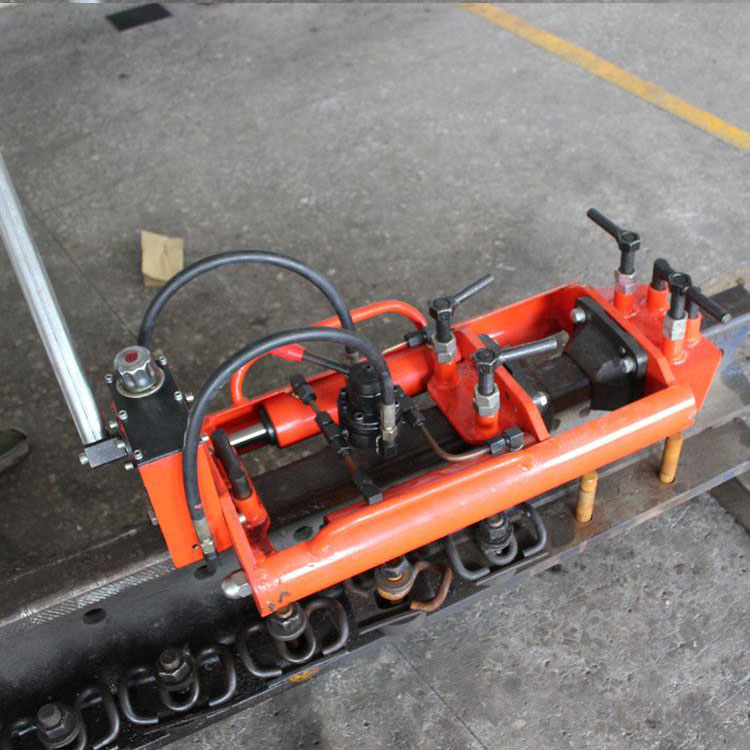

HWS-II HYDRAULIC RAIL CONVEX PUSHER

The HWS-II hydraulic rail convex pusher is a compact specialized tool designed for removing welding nodules in thermite rail welding. Compatible with all rail types ranging from 50 to 75 kg/m, it can be used both at welding bases and directly on tracks. It serves as an essential tool for stress relief and rail breakage repairs in ultra-long or interval continuous welded rail (CWR) systems.

SPECIFICATIONS OF THE HWS-II HYDRAULIC RAIL CONVEX PUSHER

| Model | HWS-II |

| Material | Stainless Steel |

| Color | Orange |

| Max. thrust (double cylinder) | 200KN |

| Max. handle working torque | 120J |

| Handle swing angle | 38° |

| Working cylinder diameter | 50mm |

| effective length | 150mm |

| Hydraulic system pressure | 51 Mp |

| weight | 75Kg |

| dimension | 800*390*400mm |

| Application | Various rails (50-75kg/m) at the depot or on the track. |